Aluminium is a noble material that has entered everyday life in various forms and thanks to its special technical/physical qualities has replaced other commonly used materials. One of the most familiar uses in the building industry is in the production of interior and exterior windows and doors (windows, shutters, gates and verandas). Aluminium has been used for many years to make windows and doors, and has grown considerably over the years into modern thermal break profiles, which have retained all the advantages of rigidity, finish, aesthetics and durability. With the new features that the current market requires in terms of energy saving, durability and acoustic comfort.

The physical/technical properties of aluminium lead us to create safe, anti-burglar, ecological and 100% recyclable frames. At C.I.MET. we make all types of frames: sliding casement, sliding parallel and tilt and turn, for maximum thermo-acoustic performance with a modern and up-to-date design, able to cover all the problems related to internal frames. All our windows and doors are no longer assembled using the old mechanical methods but by means of a breathtaking process of caulking by pressing the corners (as you can see in the link to the video below), with the insertion of high-strength extruded brackets and a special polymeric mastic that insulates the corner from infiltration and corrosion, making it suitable even for marine areas with high salinity.

In addition to the internal shutters, we also make the external ones, which, thanks to aluminium, retain all their characteristics over time, even after years of exposure to external atmospheric agents.

We also offer a wide range of products for the exterior, from classic aluminium shutters with fixed or adjustable slats to branded products such as the most sought-after original KIKAU shutters, both traditional and armoured, in aluminium with numerous wood and steel finishes that can be adapted to any home.

All our aluminium frames are assembled by means of a caulking process that guarantees stability and excludes any corrosion problems of the assembled corner.

We also make aluminium shutters for exteriors, large doors and verandas to close off terraces, and interior doors with a contemporary and modern design.

For all our products, we install low-emission glass as standard, as required by current regulations, with the possibility of Argon gas-filled glass with solar control and armoured security, to meet every single requirement with the peace of mind of a 10-year guarantee on thermal glass with double sealing to deliver a window with high thermal insulation and safety over the years.

All our aluminium windows and doors can be fitted with integrated non-visible sensors to detect (via alarm or home automation systems and a dedicated app) whether they have been opened or closed, or the correct position of the handle, so that you can always leave your home with complete peace of mind.

See product details below:

Latest generation of sliding doors

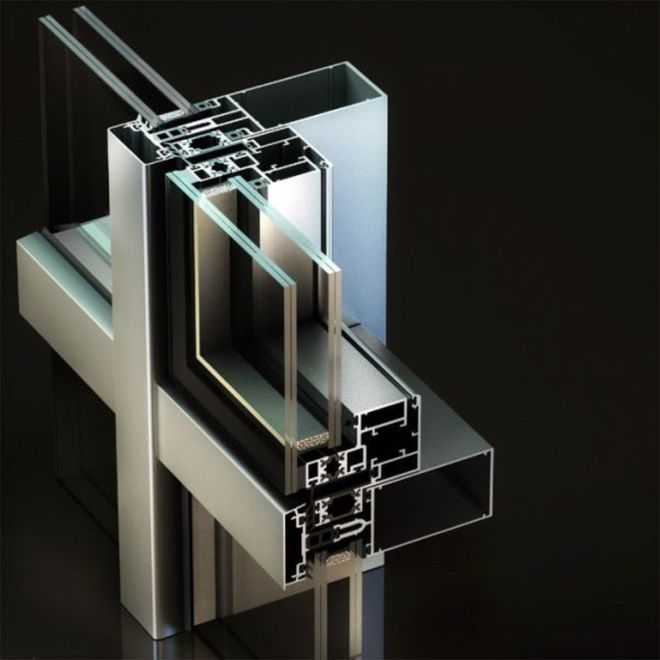

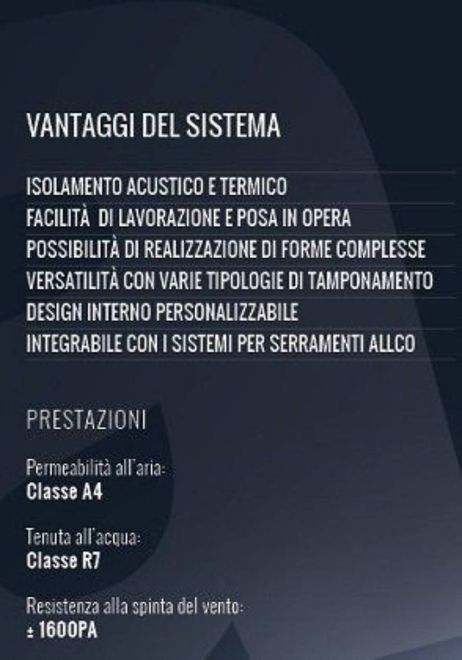

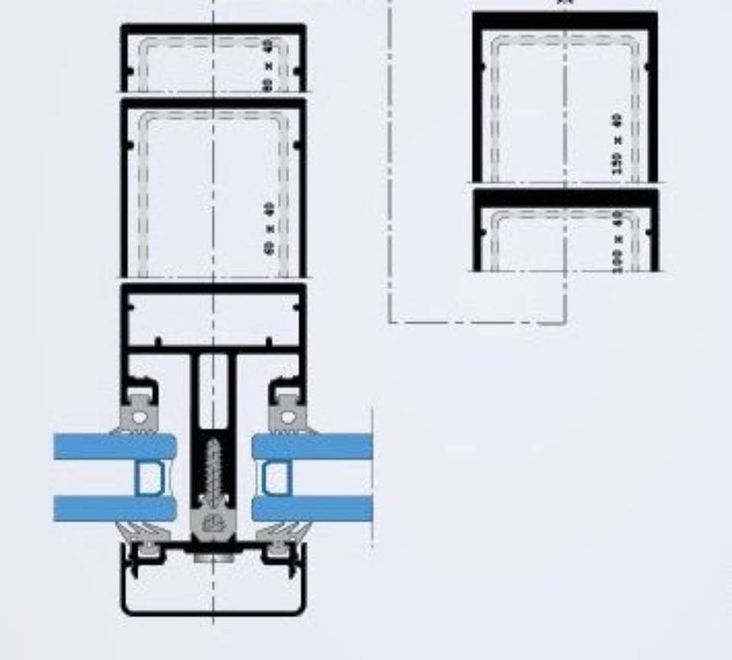

Fx 50 produced by Cimet Serramenti traditional curtain wall uprights and crossbars

Rigour and flexibility. Tradition and modernity. In its constant evolution, FX50 allco produced by Cimet Serramenti has always embodied the spirit of the times, and today it is once again asserting itself as an avant-garde, intelligent system, capable of combining the various requirements of contemporary architecture: STYLE, FUNCTIONALITY, EXPRESSIVE FREEDOM AND PERFORMANCE.

The linear and essential design with visible mullions and transoms is a modern classic that gives designers the maximum freedom to conceive complex geometric shapes, with full-glazed infills and high-tech elements that integrate with the building's solar shading, climate control and energy saving systems.

How to build a quality aluminium window frame

QUALITY COMES FROM SMALL DETAILS

Take a few seconds to watch the video that shows the care and attention we apply to every single corner we join, to make your windows more durable and safe over time. The process of welding the aluminium corners of insulating frames using a safe and certified technique.

With the help of these modern technologies and systems, each of our corners is perfect and has a better seal than traditional mechanical methods, which may not maintain the same characteristics over time, leading to corrosion inside the profiles and a degradation that leads to a much shorter life cycle of the window, with a significant environmental impact, demonstrating that a quality product improves the living environment and the world.

Aluminium download area

CATALOGUES AND DATA SHEETS FOR MORE INFORMATION (PDF FILES)

Download the catalogues below to learn more about our PVC products

Hardware download area

HARDWARE CATALOGUES

Request more information and a free quote

Don't hesitate to contact our technical department at the following number: